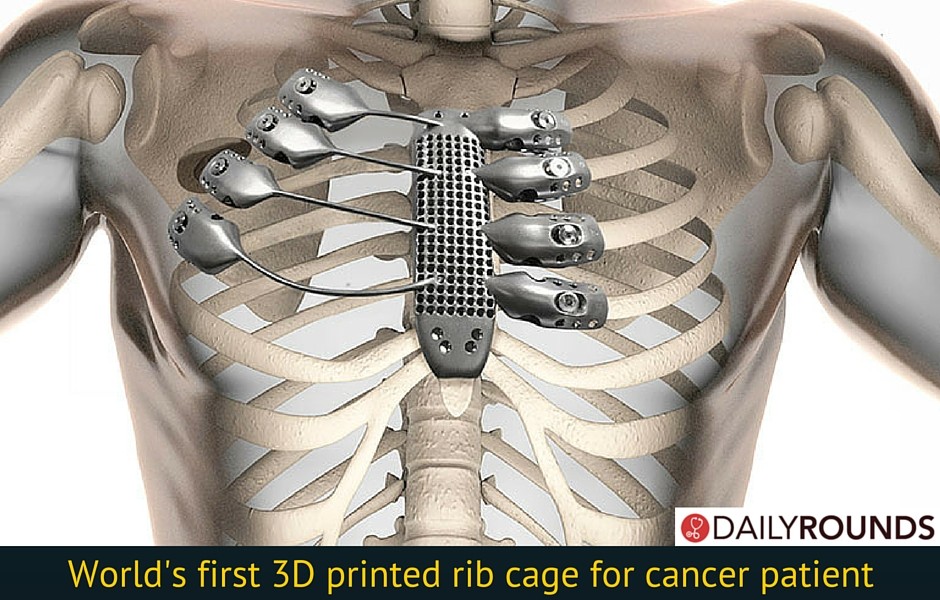

World’s first 3D printed rib cage for cancer patient

In a “world first” 3D printing has been used to recreate a new sternum and part of rib cage for a 54 year-old man who suffered from cancer.

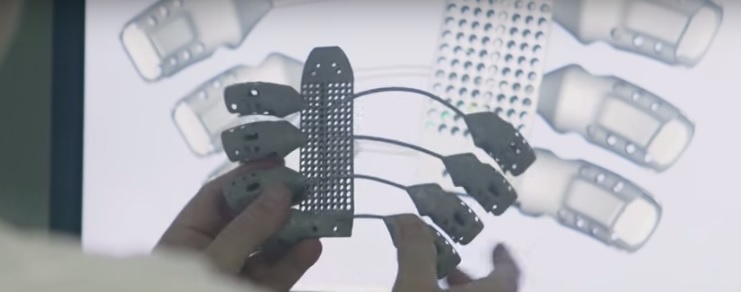

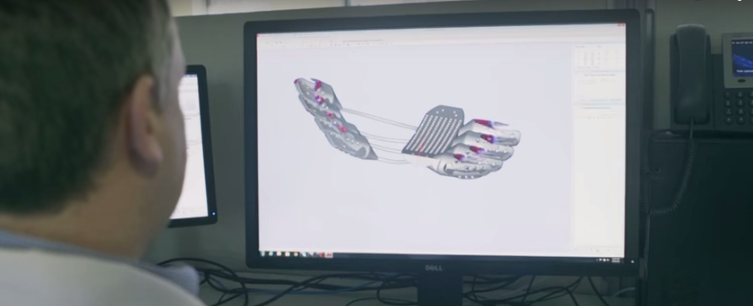

A patient in Spain suffering from chest wall sarcoma received a 3D printed replacement sternum and ribcage after many of the natural bones were surgically removed. The titanium implant was designed by Anatomics, an Australian firm, specifically for the unique anatomical needs of this particular patient. The company used CT scans of the patient and worked with his surgeons to create a 3D reconstruction of his anatomy and virtually build the implant before printing it in preparation for the surgery.

The surgery was carried out by Drs. Jose Aranda, Marcelo Jimene and Gonzalo Vereda. The procedure was performed at the Salamanca University Hospital on the 54 year-old patient who was discharged less than two weeks later and is reportedly recovering well.

The patient had suffered from a tumor in the chest wall. Surgeons knew that reconstruction would be difficult due to the complex geometry of the chest cavity and the fact that conventional titanium implants are held together by screws, which can come undone over time, causing further complications.

As Dr. Aranda says, “We thought maybe we could create a new type of implant that we could fully customize to replicate the intricate structures of the sternum and ribs. We wanted to provide a safer option for our patient, and improve their recovery post-surgery.”

And the news is good, 12 days after the surgery the patient was discharged and has recovered well.The Spanish team provided Anatomics with high-resolution CT data, from which they were able to create a 3D construction of the chest wall and tumor, allowing the surgeons to plan and accurately define resection margins.

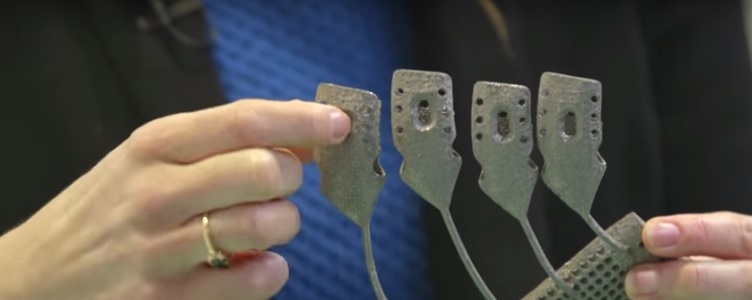

From here, a rigid sternal core and semi-flexible titanium rods were created to act as prosthetic ribs attached to the sternum. The printer directed an electron beam at a bed of titanium powder in order to melt it and create each layer. The process was repeated, layer by layer, until the implant was complete. Once completed, the implant was sent by courier to Spain, where it was implanted into the patient. Dr. Aranda pronounced the operation a success, commenting that the team had been able to create a body part that was “fully customized and fitted like a glove.”

Enjoyed reading this news story? For MORE medical discussions,image cases, MCQs and cases download the DAILY ROUNDS app for FREE! at App Store or Play Store

Original Post: CSIRO, Medical News Today, medgadget.com

Image Credits: CSIRO, Medical News Today, medgadget.com